When brothers Phil and Mose Cohen arrived in America in 1924 from Russia, they followed in the footsteps of millions of other immigrants who were processed through Ellis Island in New York Harbor.

The brothers made their way to Ohio to join family members who had already put down roots. During this time, few cities had official trash collections, so streets were littered with items that were no longer wanted. Around this same time, steel manufacturers were paying money for used metal to feed their furnaces. Many immigrants found the sentiment ‘one man’s trash is another man’s treasure’ to be true, as they collected scrap materials and then peddled their wares for income. Phil and Mose collected and sold scrap as a way to support themselves, never imagining their business would continue for four generations for the next 100 years.

Over the years the brothers married and had children and by 1947, Mose’s son, Wilbur Cohen, graduated from the University of Cincinnati with a bachelor’s in business administration. Phil and Mose invited Wilbur to join the company as a partner.

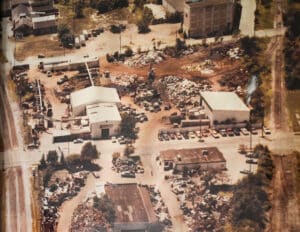

Cohen Brothers, Inc. took on more prominence in the industry in the 1950s by becoming members of the Institute of Scrap Iron and Steel. They also made a more permanent footprint when they leased a triangular piece of property owned by CSX Railroad, with auto parts yards as nearby neighbors, on Woodlawn Avenue in Middletown. They built a scale house and included office space for the brothers, as well as two secretaries.

A Country’s Need for Steel

As veterans were returning from overseas, President Theodore Roosevelt implemented the G.I. Bill, which included money for college, job training, low-interest home loans, and unemployment benefits. This newly created VA Home Loan benefit granted 4.3 million low-interest, zero down payment home loans between 1945-1955. Locally, and across the country, builders began mass-producing homes, and Cohen created a “New Steel” division focused on fabrication of custom-length I-beams and posts to meet the unprecedented demand.

“This was a natural offshoot of the scrap business because Cohen fabricated these I-beams from scrap, not from scratch – they could join together different lengths of steel beams to create the necessary length to go under a house,” explains Ken Cohen. “It speaks to the Cohen story of seeing a need and figuring out how to meet it.”

In the 1960s, the company purchased their first, of many, roll-off truck. Now they could drop roll-off boxes at customer sites and pick them up later, which helped customers with their scrap management and made loading/unloading simpler. This also resulted in the need for fewer trailers to service their customers, resulting in savings to the bottom line.

Wilbur’s sons Ken and Neil joined the company in the early 1970s. Ken took on the project of building Metal Shredders, which was a joint venture in West Carrollton. He also expanded the small, three-employee, rented Woodlawn Avenue office, which served as the company’s headquarters for more than 45 years. Neil oversaw a new facility in Hamilton, purchased from the Shepaco Paper Company.

Wilbur gave his sons both the freedom and the responsibility of learning the business from the ground up. He also wanted them to find opportunities to improve operations based on that direct experience.

“When I came to Dad’s office on my first day, he said ‘What are you doing here? Go get to work in the yard!’ It was clear he was expecting me to go out and do the work myself, not sit behind a desk in the office and be told what to do,” Ken recalls. “He told me if I wanted an office, I had to build one.”

In an effort to reduce reliance on outside suppliers and keep their fleet of trucks on the road, the brothers decided to invest in an on-site maintenance garage at the Middletown property. The first mechanic was hired in 1971.

Consumers Become Recyclers

As aluminum cans became available to the masses, consumers began thinking more about recycling. In the 1970s the now familiar triangle recycle symbol was designed and America celebrated the first Earth Day. Recycling as a moral act “for the greater good” started to become a mainstream idea, and the onus was put on consumers, rather than producers, to moderate the amount of waste being created.

It was during this time that the average homeowner could be introduced to Cohen as they had their first opportunity to recycle and visit a scrap yard.

“When aluminum cans went mainstream, everyone was able to participate in recycling,” said Geoff Rosenberg, who retired from Cohen in 2023 after 30+ years.

1980s: Securing Our Place

During the 1980s, Cohen began purchasing real estate, including the property surrounding its Woodlawn Ave. office, which was previously owned and leased by the CSX Rail company. They created lease agreements with tenants which helped their bottom line. In 1982, Cohen also took full ownership of Metal Shredders from its venture partners. In 1983, the formerly half-acre Hamilton facility expanded to eight acres. In 1985, Cohen entered into another joint venture with Muskingum Iron in Columbus, Ohio. By 1989, the now 23-acre main yard in Middletown received a much-needed upgrade: installing a drainage system, paving work areas and roadways, building a truck barn, erecting fences, and even relocating operations to more suitable areas on the property.

In 1987 the ferrous-focused Institute of Scrap Iron and Steel, of which Cohen was a member, merged with the National Association of Recycling Industries, which covered more materials, to form a new Institute of Scrap Recycling Industries. Cohen has remained an active participant in this organization, now known as the Recycled Materials Association (ReMA), giving this relatively small family-owned company a voice in the national discussion around recycling and policy-making.

A Make-or-Break Opportunity

Cohen experienced a turning point in their business in 1993. AK Steel came to town to take over the ARMCO steel mill in Middletown, which was in financial trouble, and offered Cohen the job of processing all of their scrap and being their exclusive wholesaler.

The conditions of the offer were that Cohen would have to move to an around-the-clock schedule, to match the mill’s 24/7 appetite for steel. It was a tall order, but Cohen faced the possibility that if they didn’t rise to the challenge, one of their competitors would. At the same time, with the mill under new ownership, its future was uncertain; committing to them for the long term could be risky if they couldn’t avoid bankruptcy.

Cohen took the risk, jumping into action to hire 15-20 people to create two complete shifts of operators, truck drivers, and mechanics to maintain the equipment, all within just two weeks.

Geoff Rosenberg recalled what it was like once the company decided to accept the challenge. “We had to make a huge investment in equipment. We didn’t have people to work nights and we didn’t even have lighting for people to work around the clock.”

This pivotal decision cast Cohen to the forefront and the company became recognized as the most advanced and capable scrap processor in the region, attracting the attention and respect of other industrial companies.

Becoming a Regional Powerhouse

Throughout the 1990s the Greater Cincinnati region, already a hot spot for manufacturing, saw a lot of growth in demand for industrial services like Cohen’s. The steel mill’s demand for scrap was threatening to exceed what Cohen could provide, sending them looking for new sources of scrap. At the same time, some of the competing recycling companies in the region folded or were sold, leaving an opportunity for Cohen to strengthen their position even further by acquiring equipment, accounts, and talent from the closed businesses. In a very short span of time, Cohen gained between 60-80 new accounts to service.

“All of a sudden, we are this huge company,” Geoff remembers. That was part of the motivation for Cohen to become ISO-9001 certified in 1995 to match the global quality standards that these new industrial accounts demanded.

In the coming decades, as the need for recycled metals fluctuated, Cohen was able to adapt its footprint and workforce to match. Their financial strength and stability allowed them to strategically acquire real estate that then created additional opportunities, and the flexibility to close or move yards when it was efficient to do so.

In the coming decades, as the need for recycled metals fluctuated, Cohen was able to adapt its footprint and workforce to match. Their financial strength and stability allowed them to strategically acquire real estate that then created additional opportunities, and the flexibility to close or move yards when it was efficient to do so.

At the same time as they were growing their business, the Cohen family were paying it forward with contributions to their local communities and philanthropic activities. Wilbur Cohen’s legacy of involvement in Middletown and the Jewish community in both Middletown and Cincinnati was “a frequent topic of dinnertime conversation,” recalls Neil. “He encouraged us to identify what we’re passionate about and how we could engage in and support those activities both financially and functionally.”

Some ways that Cohen functionally supports the community include longstanding partnerships and public programs. In 2011, Cohen began partnering with the Ronald McDonald House of Cincinnati to raise funds from recycled pop can tabs. In 2014, Cohen became the official Christmas lights recycling partner for Great Parks of Hamilton County and now runs an annual regional recycling drive.

Recycling & Renewal: The Next Generation

In the early 2000s, the fourth generation of Cohens joined the family business. Wilbur’s grandsons Adam Dumes and Andy Cohen came on board and began learning the business from the ground up and looking for opportunities for growth.

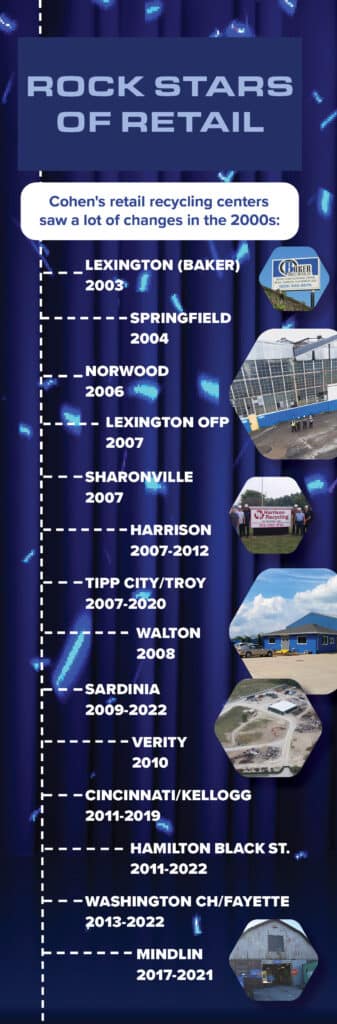

And grow they did. During the next ten years, the family was busy acquiring scrap yards throughout the region, and branching into different areas of retail and commercial recycling services.

As the business evolved, diversified, and acquired other businesses, Adam saw a need for a coherent identity to unite the workforce and represent the company to the public. Cohen Brothers Inc. rebranded to Cohen Recycling in 2011, debuting a modernized name and logo.

“Behind the brand, the name, and the logo is the idea that if you went to any of our locations, you would get the same experience there as you would at any of the others,” Adam says.

Another generational shift was also happening around the turn of the millennium: electronics were quickly becoming the fastest-growing waste stream across the world. With electronics being so reliant on metals, wires, and batteries, Cohen saw their potential customer base grow: “Not everyone has scrap metal, but everybody has obsolete electronics in a drawer, closet, or garage shelf,” Adam explains. And so the Cohen Electronics division was born.

Electronics are a little different than other scrap: it’s not just about material recovery, but protecting sensitive data. In 2012, Cohen became one of the first companies in the nation to qualify as a certified electronics recycler, held to rigorous standards for both data security and environmental impact. In 2014, Cohen partnered with the Cincinnati Reds to offer the first drive-thru electronics recycling events in the region. By 2017, Cohen Electronics was spun off into its own subsidiary, Cobalt, to distinguish the “IT asset disposition” side of the business.

Meanwhile, on the “scrap material recovery” side of the business, the 2010s saw Cohen making moves to streamline and integrate their various products and specialties and make continuous improvements.

- In 2013, Cohen Transport, Inc. was created to house Cohen’s growing fleet of trucks, trailers, and power units.

- In 2014, the CuBra (Copper & Brass) division was formally established, followed in 2016 by Stainless Steel & Alloys.

- The shredder facility in West Carrollton saw a major upgrade in 2019 that increased production, maintenance, and safety.

- In 2022, a copper chop line was added to the Verity Parkway campus.

People Powered Recycling

When you hear “recycling” you might think about protecting the planet or conserving natural resources. Cohen has always looked at it as something that starts with People.

Simply put: Metal can be recycled and equipment can be replaced. People can’t.

As early as the 1980s, Cohen put an extra emphasis on safety, making sure their employees went home from work in the same condition they arrived and encouraging a culture of looking out for each other. The ethic to “Work Safely or Not at All” is something that empowers any worker to put safety first when under pressure to cut corners or compromise. In 2015, Cohen was one of the founding members of the Circle of Safety Excellence program created by the trade organization then known as ISRI (now ReMA).

Modernization was another way the Cohens looked out for their workforce. As technology changed the way people communicated and how business transactions happened, Cohen couldn’t remain a 20th-century business forever. The historic headquarters office in Middletown, which had already been added onto over the years, was lacking office space to grow and modern amenities that would appeal to the 21st-century worker. After almost 70 years, Cohen took their home office off-site from their main scrap yard and moved into a newly renovated building just around the corner.

Improvements to key infrastructure at the home office, such as IT and security, prepared the company for what no one knew then was to come: the COVID-19 pandemic. Due to scrap recycling’s critical role in the global manufacturing supply chain, Cohen was able to keep operating through the crisis as an essential business, with minimal disruption to production or staffing.

Living the Legacy

By the time many of these changes took effect, Wilbur Cohen was entering his 90s — though he never took a retirement and was still a frequent visitor to the office. Sadly, in February of 2020, the Cohen family and community at large said their last goodbye to the man who had been the bedrock of stability and wisdom for the company for over 70 years and whose influence can be seen in every generation of leadership since he came to work for his father and uncle.

As our hundredth anniversary comes and goes, the third and fourth generation of Cohens remain actively involved in the daily operation of the business, tightly connected with their employees, and deeply committed to the same values the company was founded on. Neil Cohen continues his philanthropic work from the comfort of retirement as of 2021, while Ken, Andy and Adam continue working together to ensure that the company remains sustainable for generations to come.